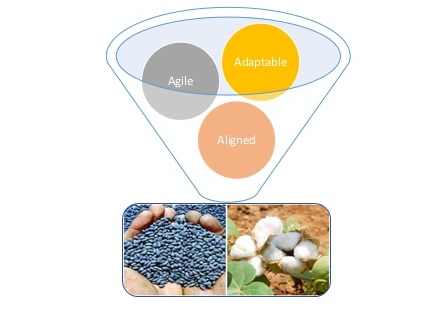

AAA – Seed Supply Chains.

Supply chain excellence doesn’t just happen. Leaders make it happen by aligning with proven standards and practices. The journey to excellence is clear provided you know how to set right your SCM practice.

If we refer to the concept of “Triple-A Supply Chain” (published in the Harvard Business Review by Hua Lee , and apply to seed supply chains , It is imperative and relevent, only supply chains that are agile, adaptable, and aligned provide companies with sustainable competitive advantage.

According to Dr Lee , Efficient supply chains often become uncompetitive because they don’t adapt to changes in the changing structures of markets. Supply chain efficiency is necessary, but it isn’t enough to ensure that firms will do better than their rivals. Only those companies that build agile, adaptable, and aligned supply chains get ahead of the competition, In the new age normal , I feel NextGen supply chains drive customer-centric processes by Building an AAA Supply Chain to Support Dynamic Business Environment.Hyper-personalisation & hyper-localisation of products & services is going to be the order of the day. In simple words is your supply chain Faster , Quicker , Flexible , Granular , More accurate and efficient ?? That is the differentiator.

The Three A’s.- By Dr lee.

Fostering Agility : Supply Chain Agility represents how fast a supply chain responds to the changes in environment, customer preferences, competitive forces etc. It doesn’t talk about random variations in executing day-to-day supply chain operations.Great companies create supply chains that respond to sudden and unexpected changes in markets. Agility is critical, because in seed industry , both demand and supply fluctuate more rapidly and widely than any industry.. Most supply chains cope by playing speed against costs, but agile ones respond both quickly and cost-efficiently. Most companies continue to focus on the speed and costs of their supply chains without realizing that they pay a big price for disregarding agility. Companies have to decide how much agile the business has to be and where in the value chain they need agility and whether it fits in well with overall strategy of the company. Sensing the change much in advance gives lot of room for companies to respond to changes in business environment. Leveraging this knowledge to proactively respond to the change with the right velocity, differentiates winners from laggards.Thus Advanced Sensing, Flexibility, Coordination and Velocity are four pillars for achieving an Agile Supply Chain.

Adapting Your Supply Chain

Great companies don’t stick to the same supply networks when markets or strategies change. Rather, such organizations keep adapting their supply chains so they can adjust to changing needs. Adaptation can be tough, but it’s critical in developing a supply chain that delivers a sustainable advantage.

Most companies don’t realize that in addition to unexpected changes in supply and demand, supply chains also face near-permanent changes. Those structural shifts usually occur because of economic progress, political/policy and social/ecosystem change, demographic trends, and technological advances. Unless companies adapt their supply chains, they won’t stay competitive for very long. The best supply chains identify structural shifts, sometimes before they occur, by capturing the latest data, filtering out noise, and tracking key patterns. They then relocate facilities, change sources of supplies/production locations , processing/packing faciliteis , and logistics infrastructures.

Creating the Right Alignment : It is the ability to have common and shared interests across the supply chain including vendors and customers.Great companies take care to align the interests of all .. If any company’s interests differ from those of the other organizations in the supply chain, its actions will not maximize the chain’s performance. Misaligned interests can cause havoc even if supply chain partners are divisions of the same company, Lack of alignment causes the failure of many supply chain practices.

Dr Hau Lee : When I describe the triple-A supply chain to companies, most of them immediately assume it will require more technology and investment. Nothing could be further from the truth. Most firms already have the infrastructure in place to create triple-A supply chains. What they need is a fresh attitude and a new culture to get their supply chains to deliver triple-A performance. Companies must give up the efficiency mind-set, which is counterproductive; be prepared to keep changing networks; and, instead of looking out for their interests alone, take responsibility for the entire chain. This can be challenging for companies because there are no technologies that can do those things; only managers can make them happen.

About Dr. Hau Lee

Dr. Lee specializes in supply chain management, information technology, global logistics, system design, inventory planning and manufacturing strategy. He is the Thoma professor of operations, information & technology at Stanford’s Graduate School of Business, the founding director of the Stanford Global Supply Chain Management Forum and the faculty director of the Stanford Institute for Innovation in Developing Economies.

Source : linkedin